Neomat, born from the alliance of Orano and XTC New Energy, unites two pillars of industrial expertise: advanced metallurgy and cutting-edge research and production of energy storage materials.

This synergy creates a project that bridges tradition and innovation, positioning Neomat as a key player across both upstream and downstream of Europe’s electric vehicle industry.

Neomat provides in Europe:

- Advanced battery material production technologies

- Localized supply solutions for the electric vehicle value chain

- Research, testing capabilities, and talent development programs

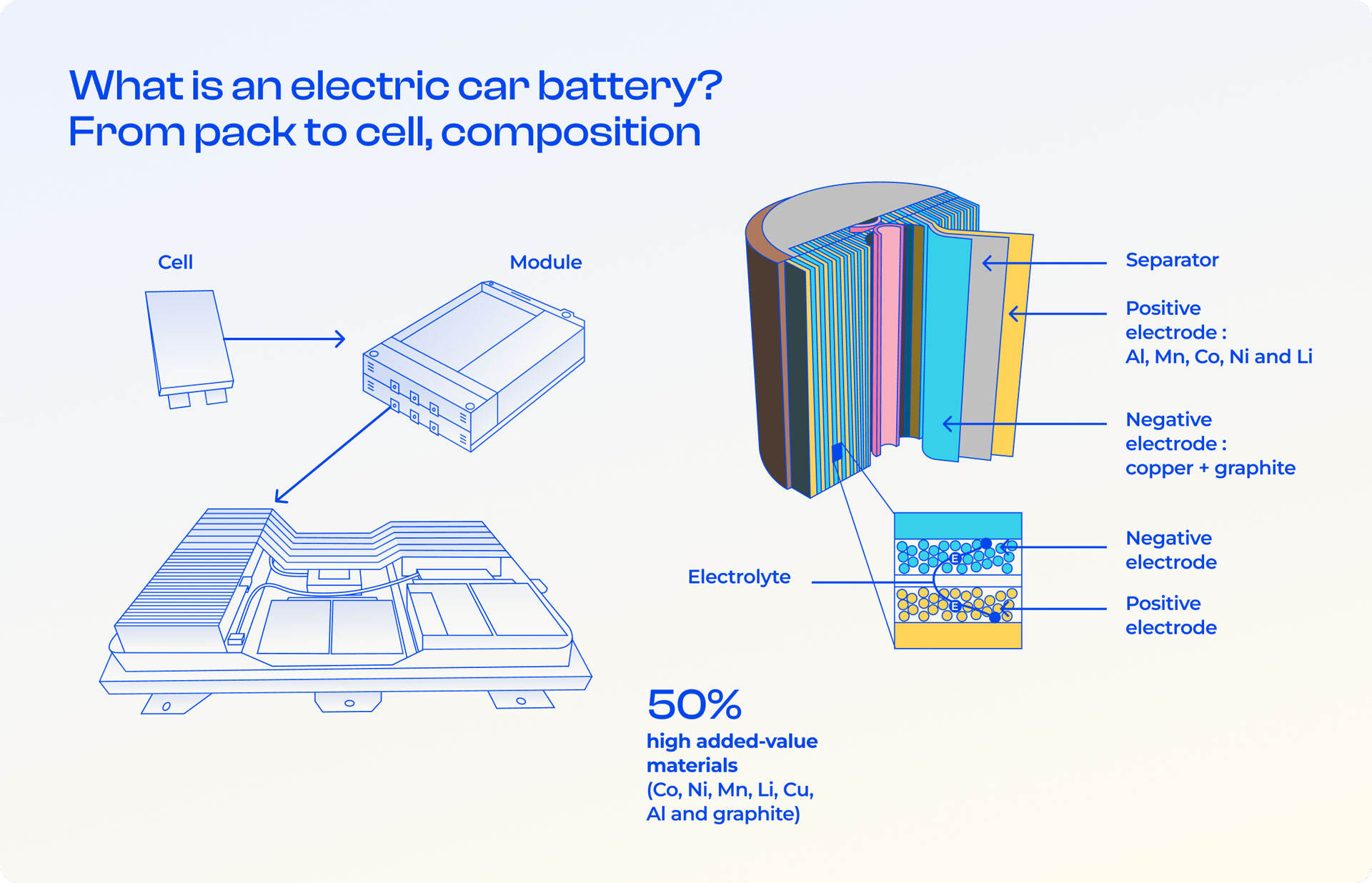

Definition: a lithium-ion battery

A lithium-ion battery consists of several modules, which in turn contain cells (=batteries), each of which has a positive electrode (i.e. a cathode) made of CAM, and a negative electrode (i.e. an anode) usually made of graphite, a separator and a lithium-based electrolyte.

- PCAM (Precursor for Cathode Active Materials): powder (mixed metal hydroxide) composed mainly of metal salts containing cobalt, nickel and manganese.

- CAM (Cathode Active Materials):

- The main component of a battery cell, determining the power and therefore the range and cost of an electric vehicle.

- To obtain CAM, which comes in powder form, PCAM must be calcined by adding lithium (‘lithiation’) as well as a coating and dopants to optimise its performance.

Neomat, synergy of an integrated CAM/PCAM platform

In the EV battery value chain, there is a strong interest in bringing key stages closer together to enhance efficiency, such as the production of cathode active materials and their precursors (PCAM).

At Neomat, we embrace this synergy by establishing two factories on the same site for both PCAM and CAM manufacturing, enabling streamlined operations and greater industrial integration,which will bring us:

- One step away between CAM and PCAM production plants, driving collaborative efficiency and reinforcing material quality management

- Significantly reduced transport distances, improving efficiency while lowering logistics costs and carbon emissions

Neomat draws on the CAM & PCAM expertise acquired by XTC over more than 20 years

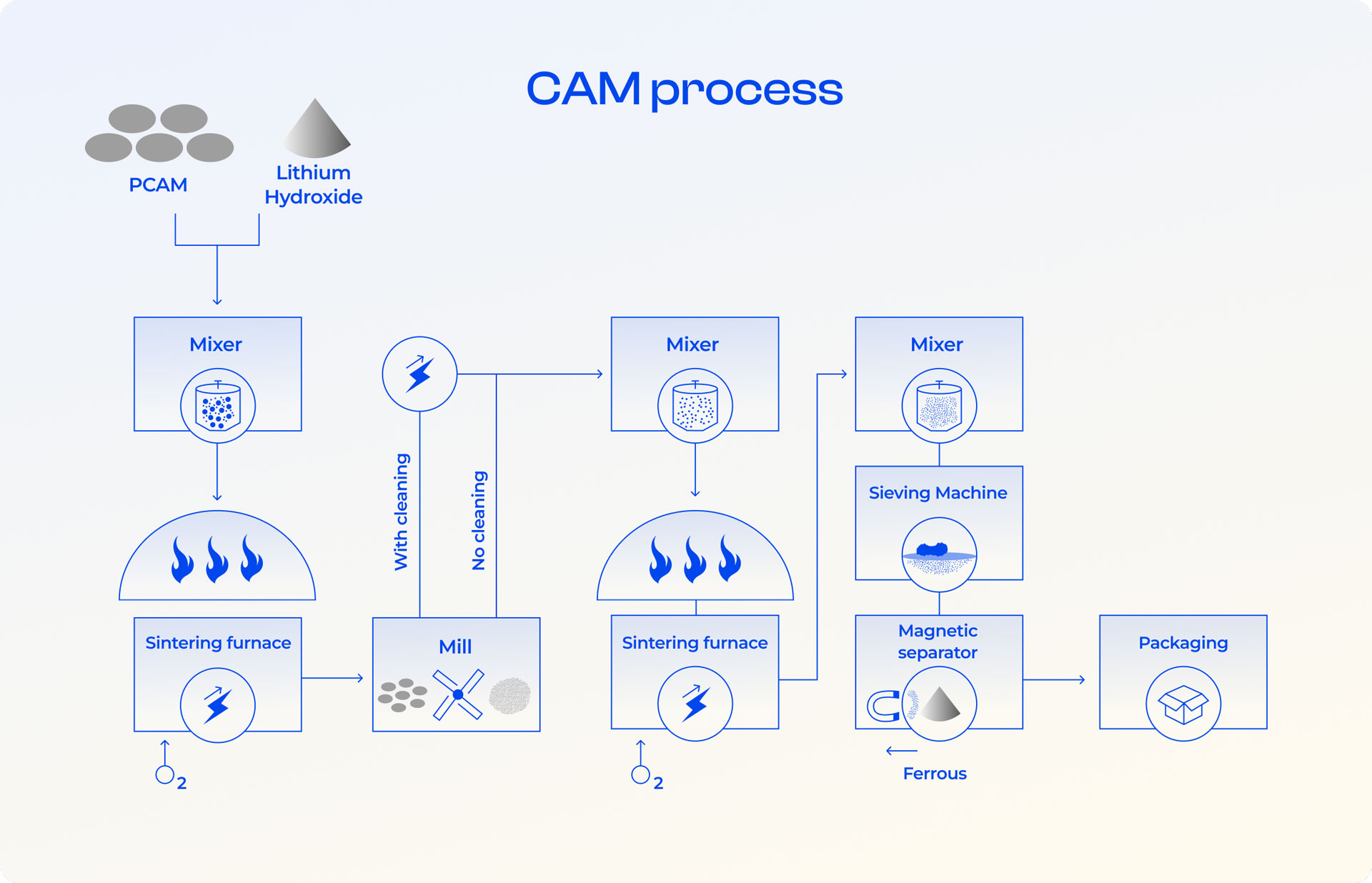

CAM

The CAMs produced in the future factory, of the NCM (nickel, cobalt, manganese) type, with a high nickel content (over 70%), are essential components of lithium-ion batteries, accounting for up to 40% of the battery's value.

Drawing on XTC New Energy's expertise in the construction and operation of similar units in China, adapted to European standards and the specific characteristics of the site, the Neomat CAM plant will consist of two identical production units with a nominal production capacity of 40,000 tons, which can be expanded to 80,000 tons of CAM.

CAMs are ‘lithiated’ PCAMs, i.e. synthesised by adding lithium. They are manufactured by mixing PCAMs (black powder) and lithium hydroxide (white powder) through successive stages of mixing and sintering, resulting in a homogeneous powder. The final phase of the process, which involves a screening stage followed by a magnetic separation stage, purifies the mixture, which then takes the form of a homogeneous black powder.

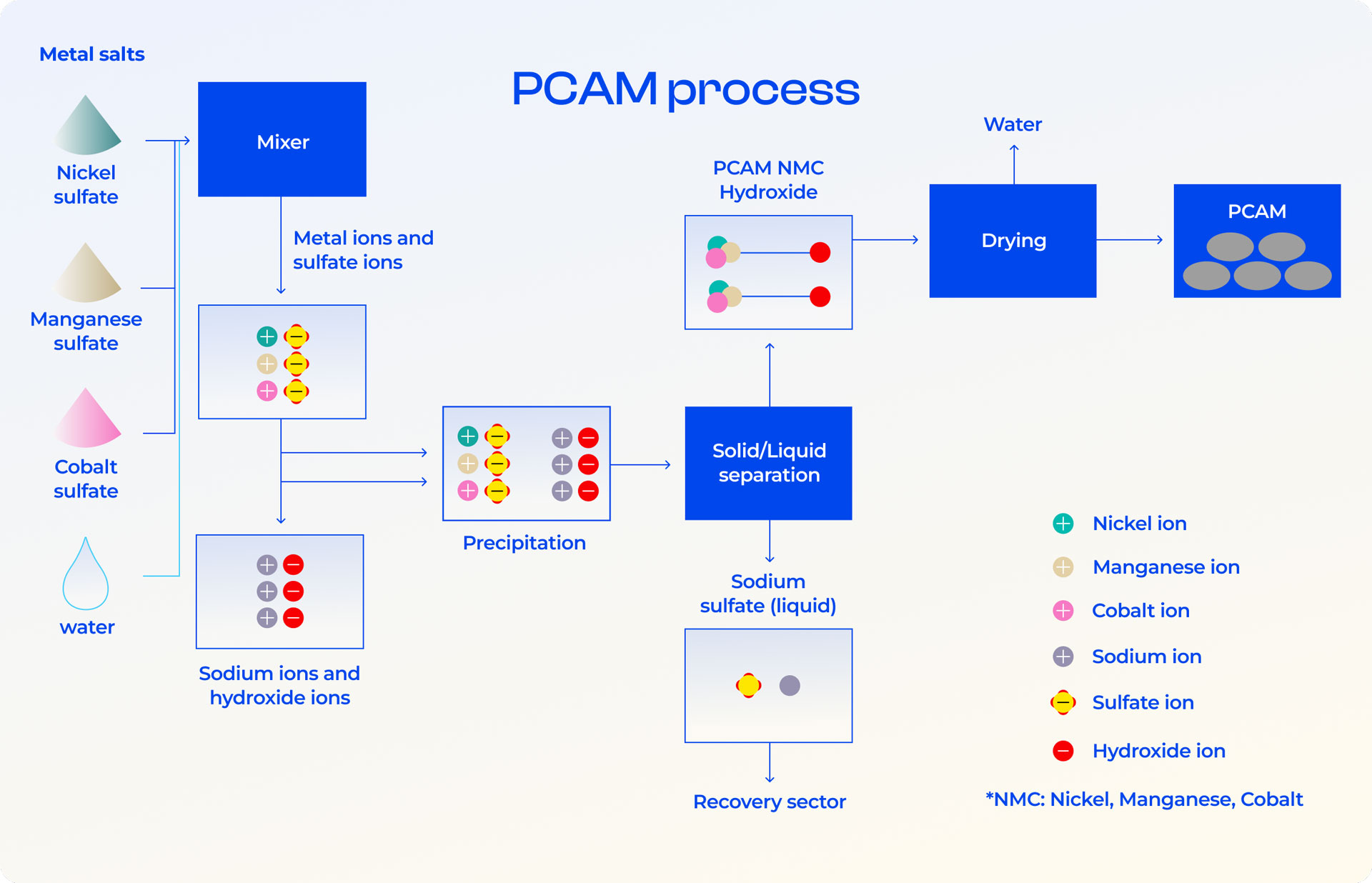

PCAM

PCAMs are industrial materials that serve as intermediates between raw materials extracted from mines and CAMs. They come in the form of black metallic powder.

Drawing on industrial experience gained from PCAM production plants operated by XTC New Energy in China and a pilot programme run by Orano in Grenoble, France, the PCAM plant will consist of two units that will eventually produce 25,000 tonnes of PCAM per year, which can be expanded to 50,000 tonnes, to supply, in particular, the CAM plant planned for the project.

The PCAM production process first involves diluting metal salts from the mining industry (nickel, cobalt and manganese sulphates) in water.

Soda and ammonium hydroxide are then added to the mixture.

This triggers a chemical precipitation reaction, resulting in two easily separable fractions: a liquid rich in sodium sulphate and PCAM in the form of nickel-cobalt-manganese hydroxide. These PCAMs, which look like spheres or grains, are dried.

Depending on customer requirements, an optional calcination step can be carried out to obtain a nickel-cobalt-manganese composite oxide, which takes the form of a black powder.