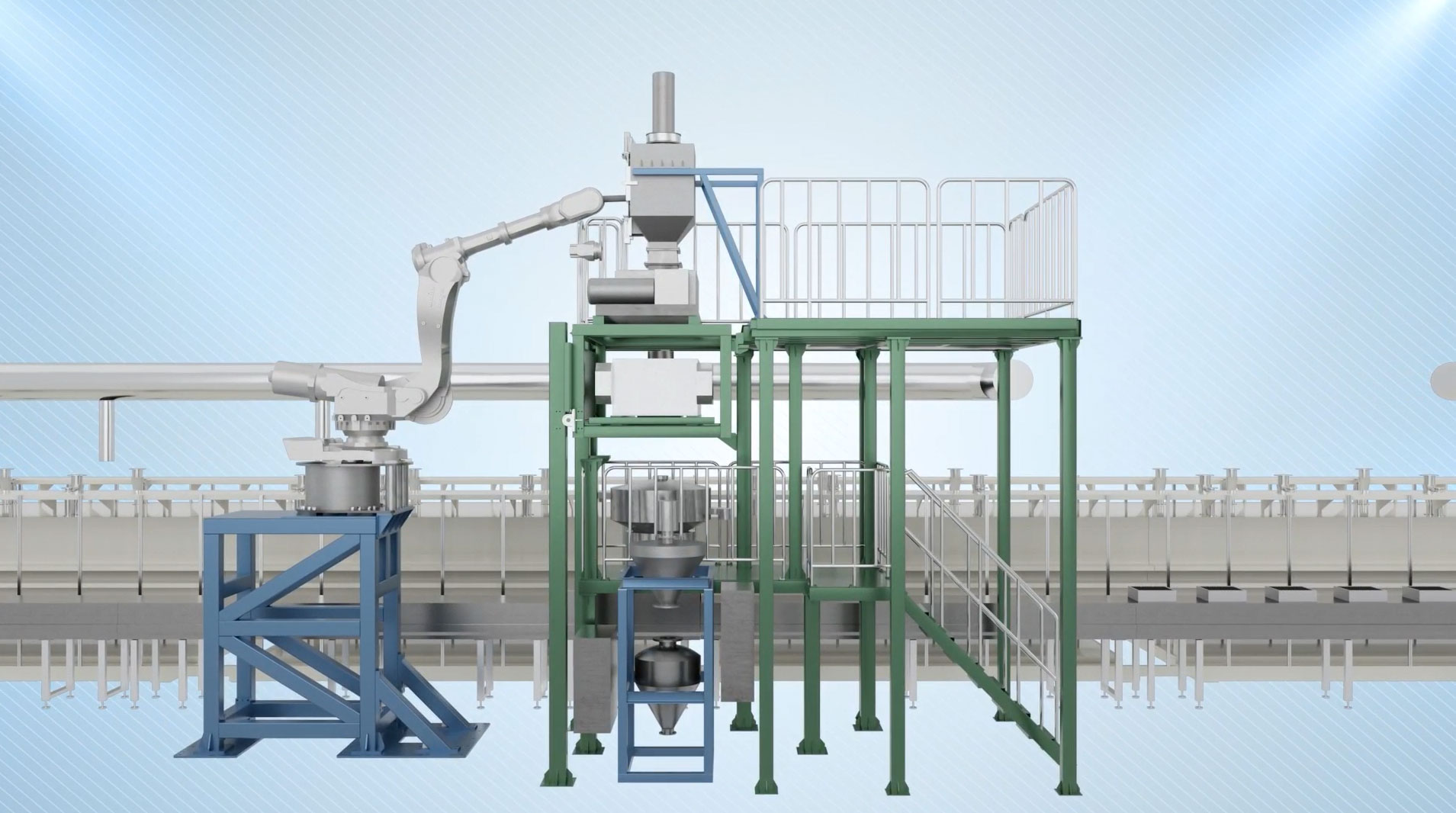

The aim here is to learn more about the products (high-nickel NCM materials, high-voltage NCM materials), their advantages and applications, as they leave the CAM factory in Dunkirk.

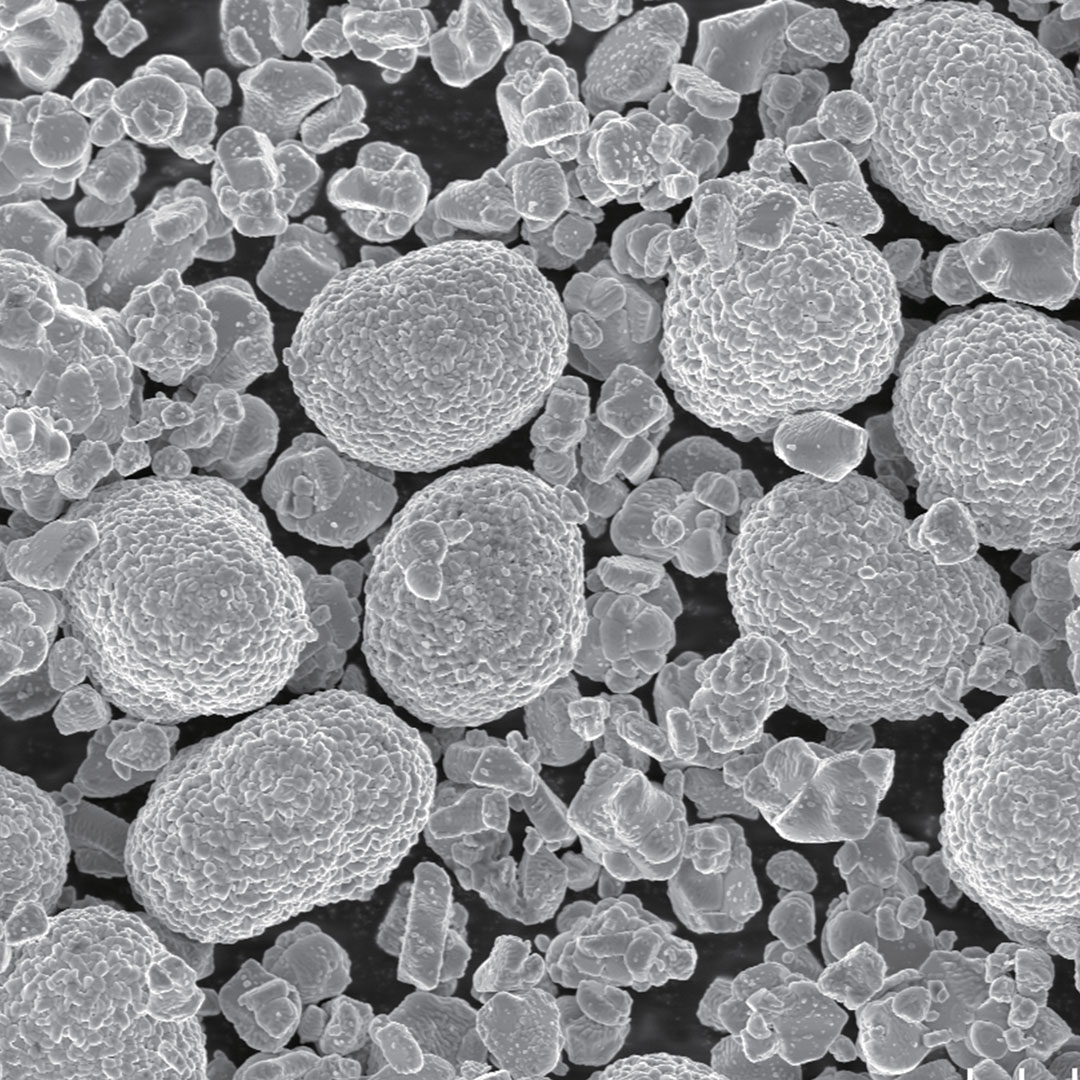

High-Nickel NCM Materials

Advantages of High-Nickel NCM Materials

- High Discharge Capacity: Full electric 1/3C capacity reaches 210–215 mAh/g.

- Excellent High-Temperature Cycling: At 45 °C, capacity retention remains at 92% after more than 1,200 cycles.

- Fast-Charging Capability: Supports 4C rapid charging.

- Low DCR Growth: Demonstrates minimal DCR increase in bi-modal sample testing.

- Strong Versatility: High adaptability across multiple application scenarios.

Applications:

- Electric vehicles

- Construction machinery

- Robotics

- Energy storage systems

High-Voltage NCM Materials

The group XTC has been engaged in the research, development, and production of high-voltage NCM materials since 2015. Through proprietary design, the company precisely regulates the ratio of nickel, cobalt, and manganese in different formulations, and applies a controlled crystallization method to produce NCM precursors. In addition, advanced techniques are employed such as multi-element doping and integrated doping-coating processes to manufacture NCM materials.

These innovations have successfully overcome the key technical barriers of high-voltage NCM materials, resulting in products with excellent power performance, long cycle life, high consistency, strong stability, and outstanding electrochemical properties. XTC’s high-voltage NCM materials have already entered the supply chain of mainstream power lithium battery manufacturers, earning broad market recognition as high-performance battery materials. NEOMAT CAM will also produce this product line at its Dunkirk facility.

Advantages of High-Voltage NCM Materials

- High Voltage: Operates above 4.4 V, delivering energy performance comparable to high-nickel batteries.

- High Power Output: Supports discharge rates up to 30C.

- Fast-Charging Capability: Enables rapid charging at 3C–10C.

- Extended Lifespan: Long cycle life with stable performance over time.

- Enhanced Safety: Excellent thermal stability ensures safe operation and non-flammable battery performance.

Applications

- Electric vehicles

- Internet of Things (IoT) devices

- Smart meters

- Residential power supply systems

- Drones

- Electric tools