Orano, which has mastered recycling technology, has implemented an innovative process that safely recovers and purifies materials of interest at a very high level (over 95%) for reuse in new battery module components.

Recycling on an integrated platform for stronger efficiency

The future recycling plant, located on the same industrial platform as the CAM and PCAM factories, will be able to process end-of-life batteries and production scraps from gigafactories, as well as recycle production waste from the two CAM and PCAM plants (Neomat plants), with the aim of creating a virtuous circular economy for materials of interest.

The hydrometallurgical recycling plant would enable the recycling of 15,000 tonnes of black mass per year, with the potential to reach up to 30,000 tonnes/year.

The future innovative recycling plant at a glance

The recycling plant:

- Is based on a set of technologies that break with existing processes, enabling the recovery of all materials from Li-ion batteries and the manufacture of new cathode materials.

- Is based on a process with a reduced environmental footprint (low energy consumption and high recycling rate).

- Creates significant added value by integrating the manufacture of new materials for future batteries into a circular economy model.

- Enables up to 100% of battery modules to be recycled and is versatile enough to process all types of batteries on the market.

Orano, an industrial expertise

with a capacity of 15,000 tons/year of recycled black mass, with a full capacity of 30,000 tons/year

European Regulation of 08/17/2023, applicable since 02/18/2024

2031, minimum targets have been set for the recycling of batteries and materials of interest: 16% Co, 85% Pb, 6% Li and 6% Ni. By 2036, these targets will be raised to 26% Co, 85% Pb, 12% Li and 15% Ni.

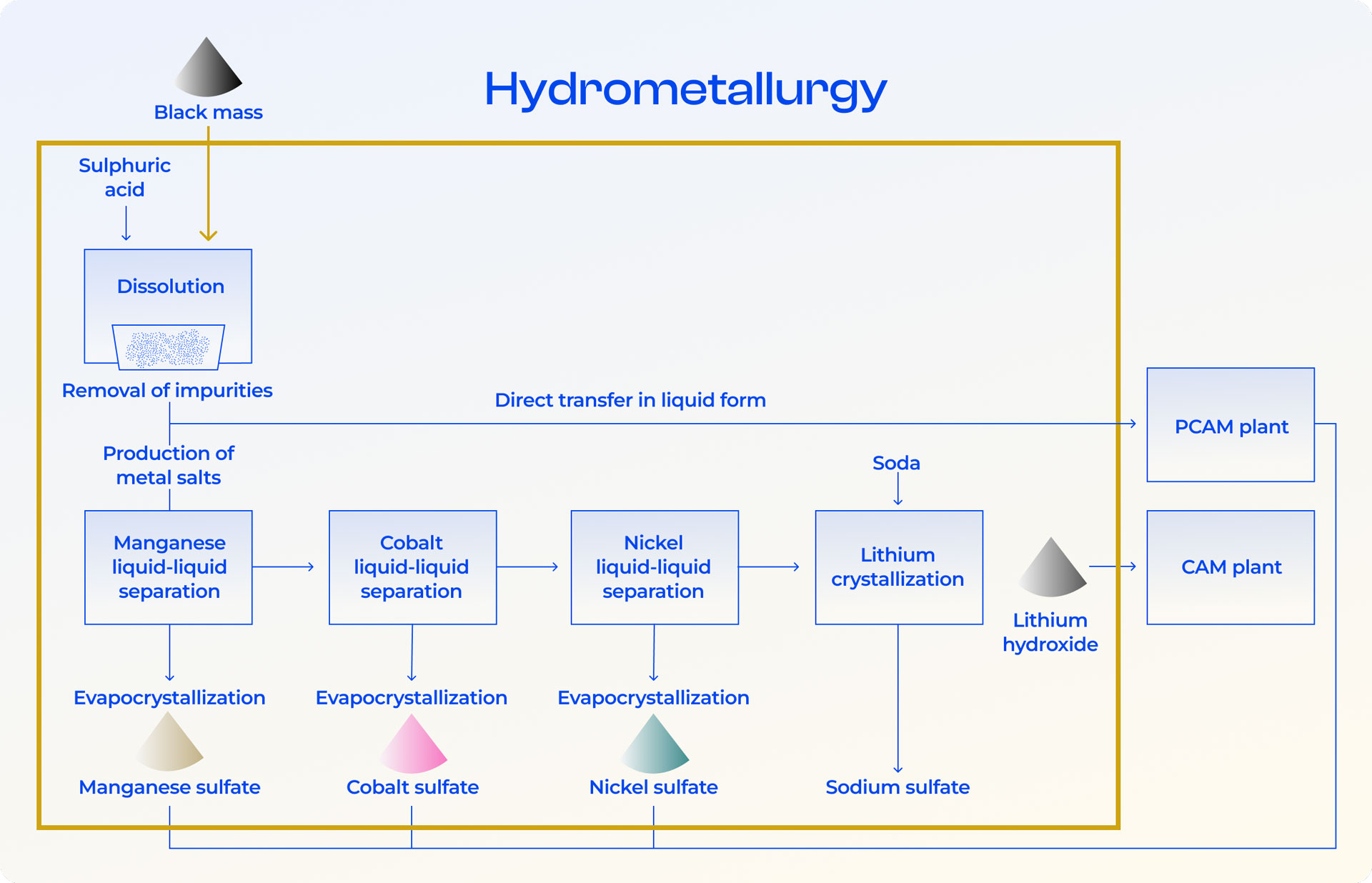

Recycling through hydrometallurgy

Hydrometallurgy involves chemically treating metal powder in water to separate strategic materials. Compared to pyrometallurgy, which involves very high temperature processes (from 800°C to 1,500°C), hydrometallurgy requires less energy.

It consists of several stages:

- dissolution of the ‘cathode mix’ or ‘black mass’ in water;

- selective precipitation of impurities using various reagents: soda and sulfuric acid;

- liquid-liquid separation to separate the elements of interest. This stage produces pure (liquid) solutions of manganese, cobalt, nickel and lithium.

- evaporative crystallisation to convert these solutions into salts.

The output products are metal salts (cobalt, nickel and manganese sulphates) and lithium hydroxide. These can be reintroduced into the PCAM plant (for NMCs) or CAM plant (for lithium), replacing materials sourced from mining. Other products – whether recoverable or not – are also recovered.

The proximity of the PCAM plant also makes it possible to consider, for some of the metals processed in recycling, carrying out only the first two stages – the purified solution containing cobalt, lithium, manganese and nickel is then directly reintroduced into the PCAM process, avoiding separation and evaporative crystallisation.

The hydrometallurgy process in video

Orano's hydrometallurgy project, the only one in France recognised by the European Commission as a strategic project

On 25 March 2025, Orano's hydrometallurgy project to recycle electric vehicle battery components in France was declared a strategic project by the European Commission under the Critical Raw Materials Act (CRMA), alongside 46 other European industrial projects. Six projects concern battery recycling: Orano is the only project recognised as such in France.

As a reminder, the CRMA aims to secure supply chains for critical materials in order to strengthen European sovereignty. Orano's action is fully in line with this objective.

The Recycling (REC2) and PCAM projects, Grant Innovation Fund Award

On 3 November 2025, the Recycling plant project (named REC2) and Neomat PCAM plant project received the Grant Innovation Fund from the European Commission, considering that this cutting-edge project in the field of ‘net zero’ technology aims to strengthen Europe's technological leadership and accelerate the deployment of innovative decarbonisation solutions.